Gauges

Showing all 9 results

-

CP Pressure Gauge

Capsule Type Pressure Gauge, manufactured in stainless steel in the EU to EN837CP Pressure Gauge

Manufactured in stainless steel within the EU, in accordance with EN837 standards. This product is designed for use in corrosive environments and is resistant to chemical attack. The standard capsule material is stainless steel, AISI 316. The CP capsule type pressure gauges are suitable for a wide range of low pressure applications in industries such as oil and gas, chemical, petrochemical, refining, power and marine, on dry and clean gasses, air, and exhaust gasses from chimneys.

Key Features

- Degree of Protection IP55

- Nominal Diameter of 100 & 150 mm

- Stainless steel enclosure as standard

- Blowout Protection

-

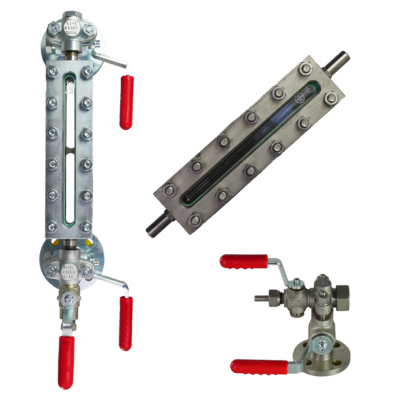

Level Gauges

Glass Tube, Reflex & Transparent TypesLevel Gauges

These level gauges provide high reliability for use in steam and process applications, specifically saturated steam, hot water and aggressive fluids.

These are available in either Glass Tube, Reflex or Transparent Types and have been used in industrial boilers and chemical aggressive media.

Made from borosilicate glass with spare shut off valves available.

-

GG Pressure Gauge

All stainless steel, Bourdon tube, manufactured in the EUGG Pressure Gauge

The GG pressure gauge offers customer a cost-effective and accurate solution to their individual process requirements. It is manufactured in stainless steel, has a Bourdon Tube and is manufactured within the EU according to EN837 standards.

- All stainless steel

- Manufactured in the EU, according to EN837

- Nominal Diameter options of 63, 100, 150, 200 and 250 mm

- Degree of Protection IP55/IP67

- Stainless steel enclosure as standard

- Blowout Protection

- Ranges available between -1 bar to 1000 bar

- Monel pressure connection, material and options available

-

SG Pressure Gauge

Diaphragm Pressure Gauge, manufactured in stainless steel in the EU to EN837SG Pressure Gauge

Manufactured in stainless steel within the EU, in accordance with EN837 standards. This product is designed for use in corrosive environments and is resistant to chemical attack. The standard diaphragm material is stainless steel, AISI 316 Ti, but other materials are available upon request. The rugged SG range of diaphragm pressure gauges are suitable for a wide range of applications in industries such as Oil and Gas, Chemical, Petrochemical, Refining, Power and Marine.

Key Features

- Degree of Protection IP55/IP67

- Nominal Diameter of 100 & 150 mm

- Stainless steel enclosure as standard

- Blowout Protection

-

Differential Pressure Gauge – DB Series

Double Bourdon Tube, 100, 150 options available, Manufactured in the EUDifferential Pressure Gauge – DB Series

All Stainless Steel execution, making it suitable for a range of applications in process plants and OEM equipment. The robust nature of this product allows it to be used in hazardous areas, 1 and 2, to work with SIL2 safety related systems and corrosive atmospheres. Like many Delta Mobrey products, this gauge can be modified should the customer require it.

Key Features

• Nominal Diameter of 100 mm.

• Degree of Protection IP55/65/67.

• Stainless steel enclosure as standard.

• Ranges available between 1 and 60 bar.

• Accuracy class 1.6%. -

DG Differential Pressure Gauge – DG range

Single or double diaphragm, 100, 150 All stainless steelDG Differential Pressure Gauge – DG range

The DG diaphragm operated differential pressure gauges offers customer a cost effective and reliable solution to their process control requirements. This range comes with the Single and Double diaphragm construction to suit a wide range of over pressure and measuring range requirements. Available in variety of wetted part material, the DG differential pressure gauge can be used for variety of applications.

Key Features

- Nominal Diameter of 100 mm and 150 mm

- Degree of Protection IP55/IP65/IP67

- Stainless steel enclosure as standard

- Blowout Protection

- Ranges available from 0 to 25mbar, up to 0 to 25bar.

- Monel pressure connection, material and options available for double diaphragm construction

- Double & single diaphragm construction depends to range & static pressure & wetted part materials

-

Bimetal Temperature Gauge – GB Series

Stainless steel, rigid or every angle, made in the EUBimetal Temperature Gauge – GB Series

Stainless steel enclosure and is manufactured in the EU. The BG range is suitable for a wide range of applications in multiple industries where a safety barrier and blow out back are required to give added security.

Key Features

•Nominal Diameter options of 100mm, 125mm and 150mmSt. Steel case.

•With rigid or every angle stem.

•Watertight casing stainless steel execution

•Indication ranges range between -50 to +500 °C

•Version B: made with the traditional criteria of quality and versatility whilst also satisfying the specific needs of delivery and flexibility

•Version S: a very good quality level and offers considerable economic advantages due to updated product modern technologies. -

Expansion Temperature Gauge – GE Series

All stainless steel, direct or remote, made in the EUExpansion Temperature Gauge – GE Series

Manufactured in the EU, using a stainless steel enclosure, the two versions of these gauge can be configured for different industrial applications. For dry applications the product is more standard. However, for industries where the level of vibration needs to be considered this product comes with a fluid filled case.

These two variations make the GE Expansion Temperature Gauge a product that can work with hazardous environments such as chemical and petrochemical, pharmaceutical and nuclear power plants.

-

Pressure Gauge – GS Series

Cost effective with safety prioritisedPressure Gauge – GS Series

The GS solid front safety pattern pressure gauges offers customers a cost- effective and reliable solution to their arduous process control requirements.

This pressure gauge is designed with extra emphasis on ‘Safety’. Safety is guaranteed by a protective baffle wall positioned between the pressure element assembly and the dial, and by a backplate blow-out device which allows emergency pressure venting.

Available with a wide variety of casing options and sizes, the GS pressure gauge can be used for a variety of applications when pressure measurements are needed. Oil and Gas, Chemical, Power and the Food Industry are just a few who utilise this robust pressure gauge.