By 2027, the waste to energy market is expected to be valued at 50.1 billion US dollars, with further growth being expected. Financial focus is being shifted away from fossil fuels and to focus on more renewable forms of energy.

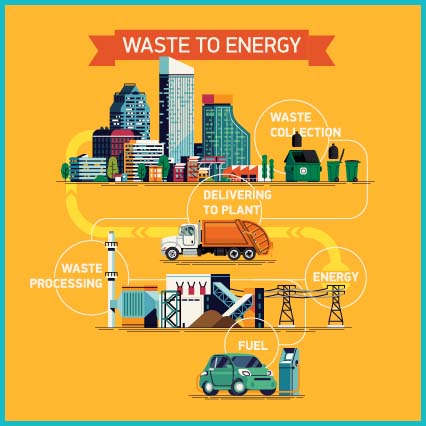

Waste to energy (WTE), is where waste is burnt at high temperatures which is used to heat water in a boiler. The steam created is used to turn turbines, which generate electricity. Detailed planning is needed to ensure the integrity of the process and to ensure safety. Waste to energy has been viewed with concern because of the emissions released from the facility. While many pre-incineration processes, such as the removal of ferrous metals, have reduced the amount of pollutants emitted, the economic viability of the process has been questioned.

New incinerators meet stricter regulations on pollution to reduce further the emissions. Improved process methodologies and newer technologies are allowing for further development of this energy option, looking at achieving economic viability.

Regional Growth

The waste to energy industry has had significant growth in Europe, with China and Japan becoming increasingly interested in developing this form of energy. Increasing government funding for municipal solid waste management along with growing awareness of waste to energy in countries such as India, Singapore, Indonesia and Thailand are expected to push regional market growth.

There are over 400 waste to energy facilities within Europe, and another 300 across the globe. 75 (as of 2023) are in the US, divided mainly between New York and Florida. However, rapid expansion is liked as the rising industrial and domestic waste is prompting regional governments to promote energy generation from waste.

In waste-to-energy, Germany, the UK, and Italy are the most engaged countries in Europe. There are currently about 100 waste incineration plants in Germany alone, with a workforce of 6,000 and total annual capacity of about 20 million tonnes. The UK and Italy are looking to expand further.

Waste Reduction Ratio

According to the US Environmental Protection Agency, there is a one ton reduction in greenhouse gases for every ton of solid waste. The energy production is being investigated further to ensure economic viability. The US Department of Energy made the following recommendation in August 2019, and this has been implemented in most facilities across the world.

“Reduce operating costs and increase revenues in existing incinerator facilities. These opportunities include advanced emissions control strategies to lower costs associated with environmental compliance, development of novel corrosion-resistant materials to reduce maintenance costs, and advanced separations to recover valuable materials from ash.” – Office of Energy – Efficiency Renewable Energy Report August 2019.

Continued Development

Continual development of the process, such as the removal of ferrous metal, demonstrates the fluidity of the waste to energy process. As technology progresses, adjustments can be made to improve the levels of efficiency within the plant, and also in the production of energy via steam.

Process instrumentation plays an important role in the operation of any such plant, and Delta Mobrey has already worked with several waste to energy plants. We have provided expertise and solutions needed to keep such plants in operation. Delta Mobrey’s Hydrastep system has been used in many waste to energy plants to monitor the boiler drum interface levels and ensure their safe operation, while pressure and temperature instruments measure other critical parameters.

Like most new technologies, there is continual development focused on making this method of energy production both financially and environmentally viable.

About Delta Mobrey

For more than 100 years, Delta Mobrey Limited has been a world-leading specialist in the design and manufacture of quality process instrumentation for the measurement and control of fluids and gases in all industrial plant and equipment.

Trusted quality – proven value: quality and reliability have always formed the cornerstone of our success, recognised by industry with international approvals covering every aspect of our manufacturing and product portfolio, together with certifications spanning all areas of hazardous and regulated environments.

Global team – local support: as a global organisation, Delta Mobrey is totally committed to delivering the best possible customer service and technical support, ensuring a lifetime value of ownership, together with a flexible and responsive approach to meet our customers’ individual demands.